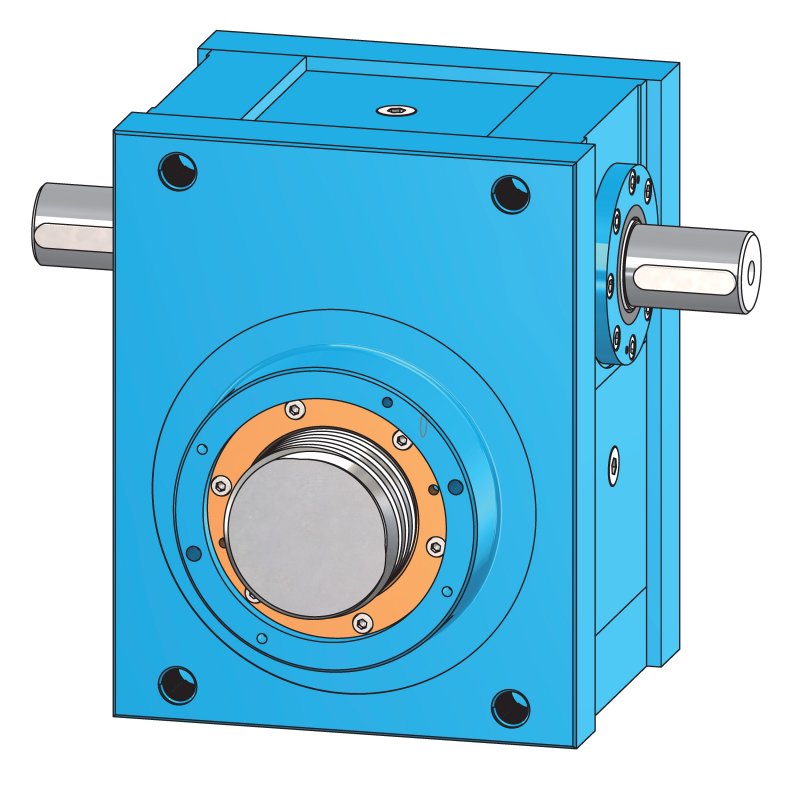

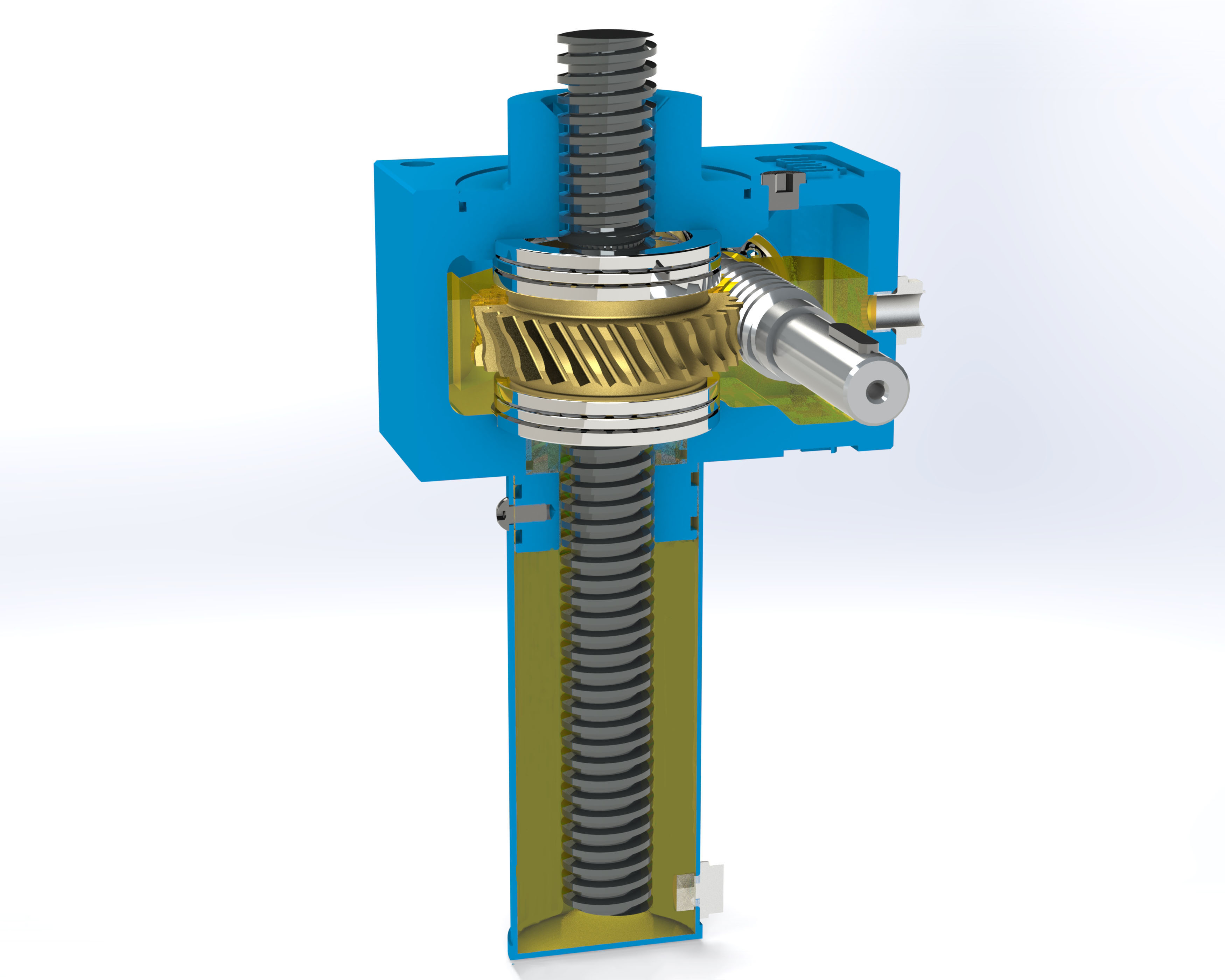

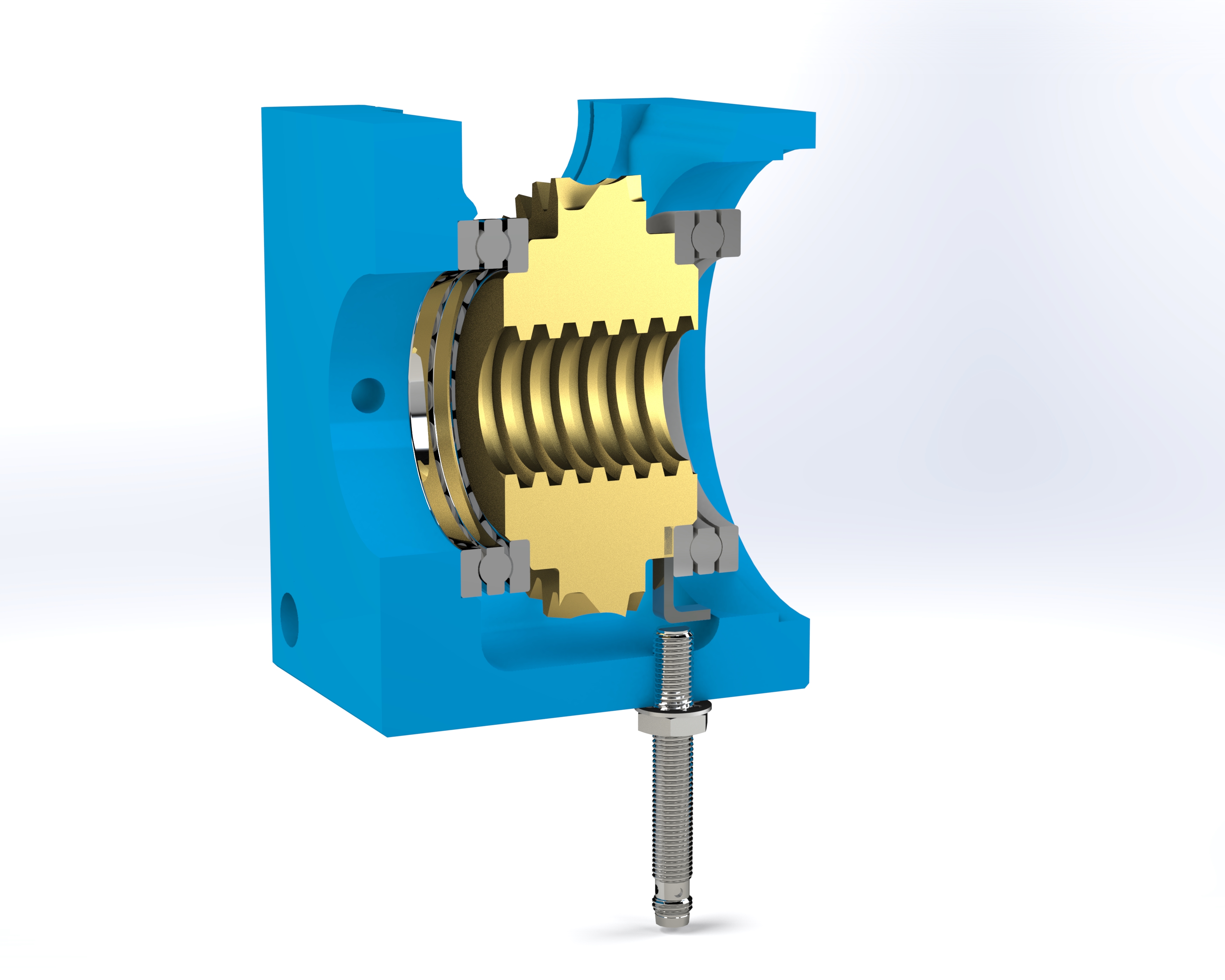

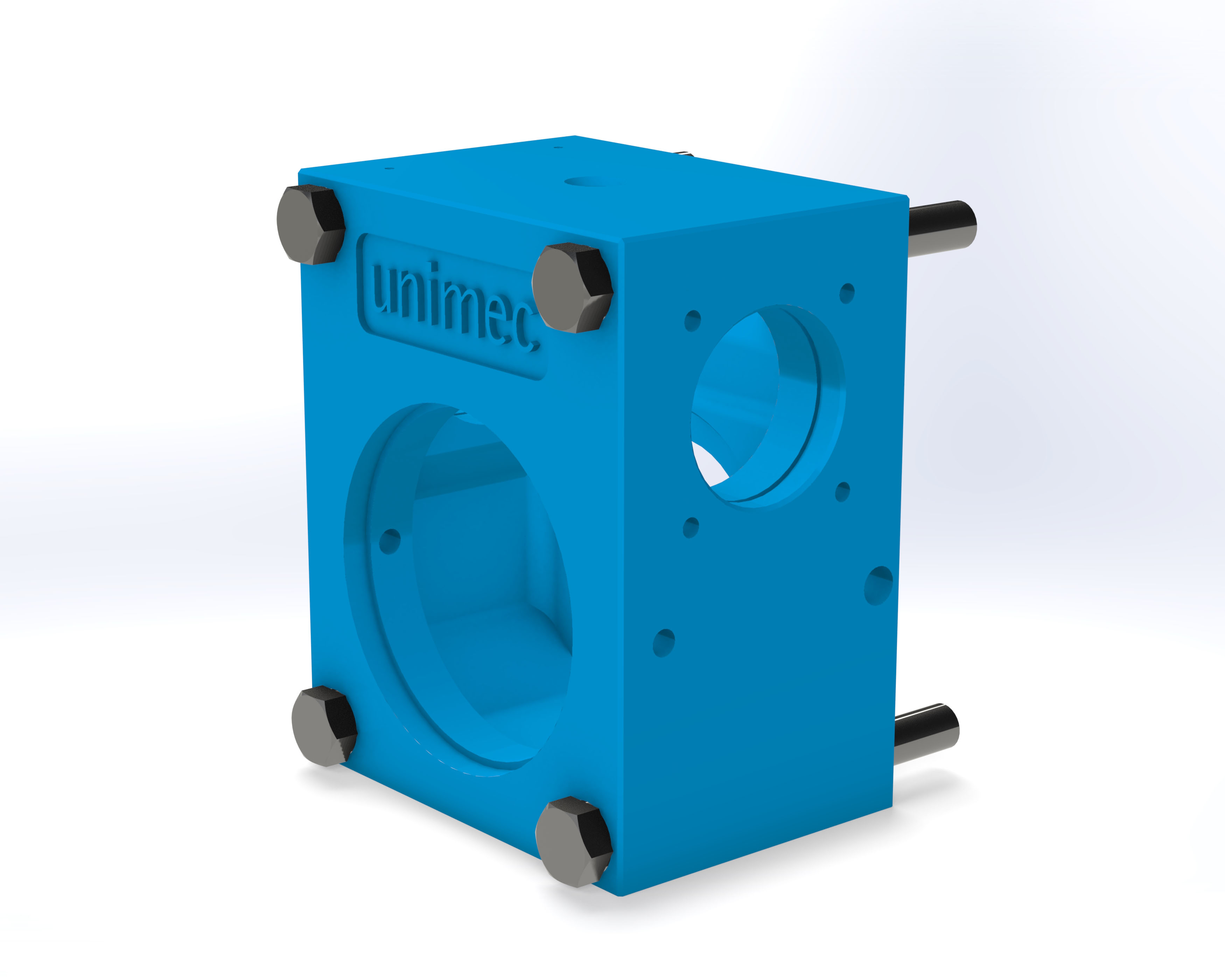

Trapezoidal Screw Jacks

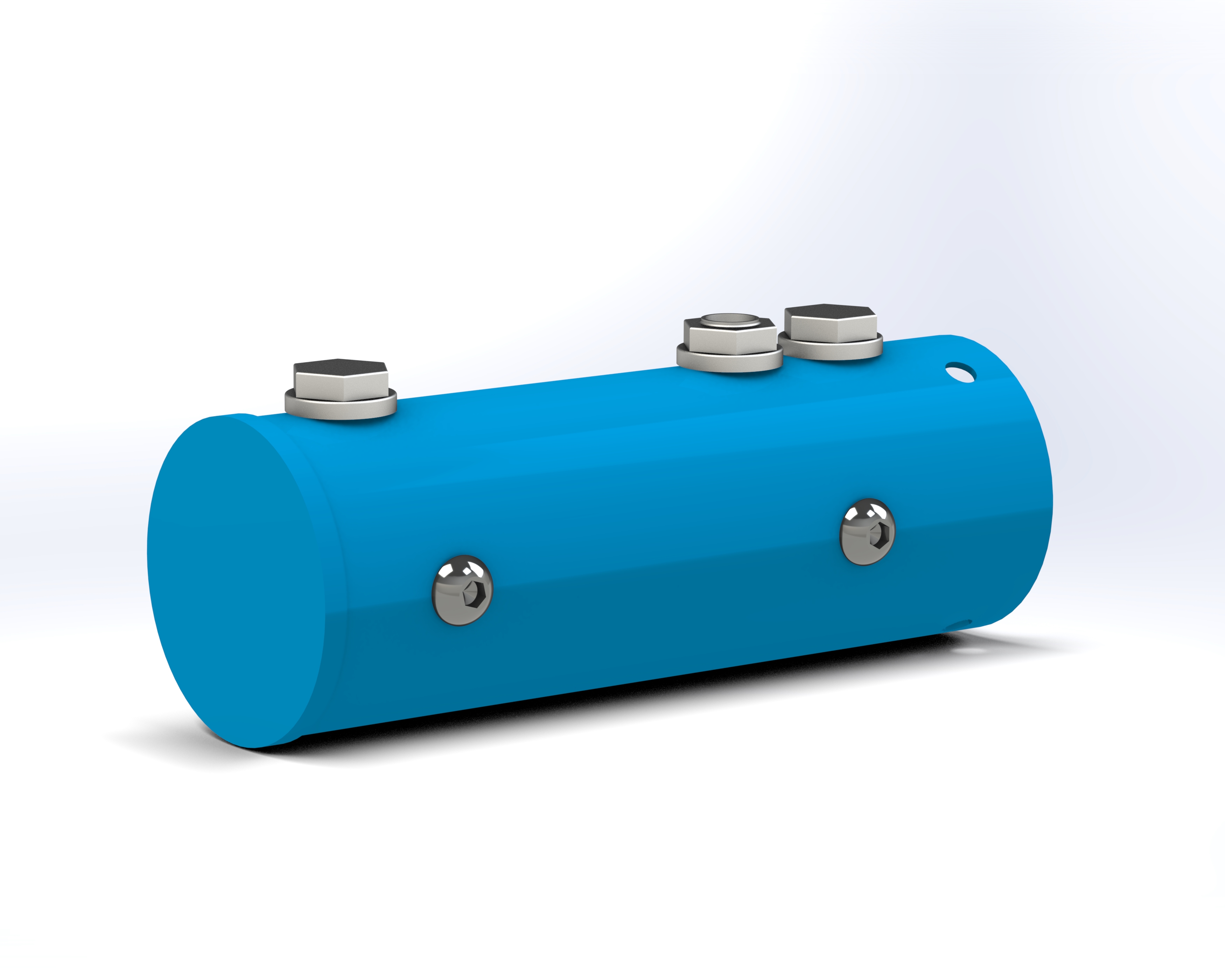

Size 12014

60 ton - 600 kN

Model TP

Materials

| Material | Normative | Specification | Indications | |

|---|---|---|---|---|

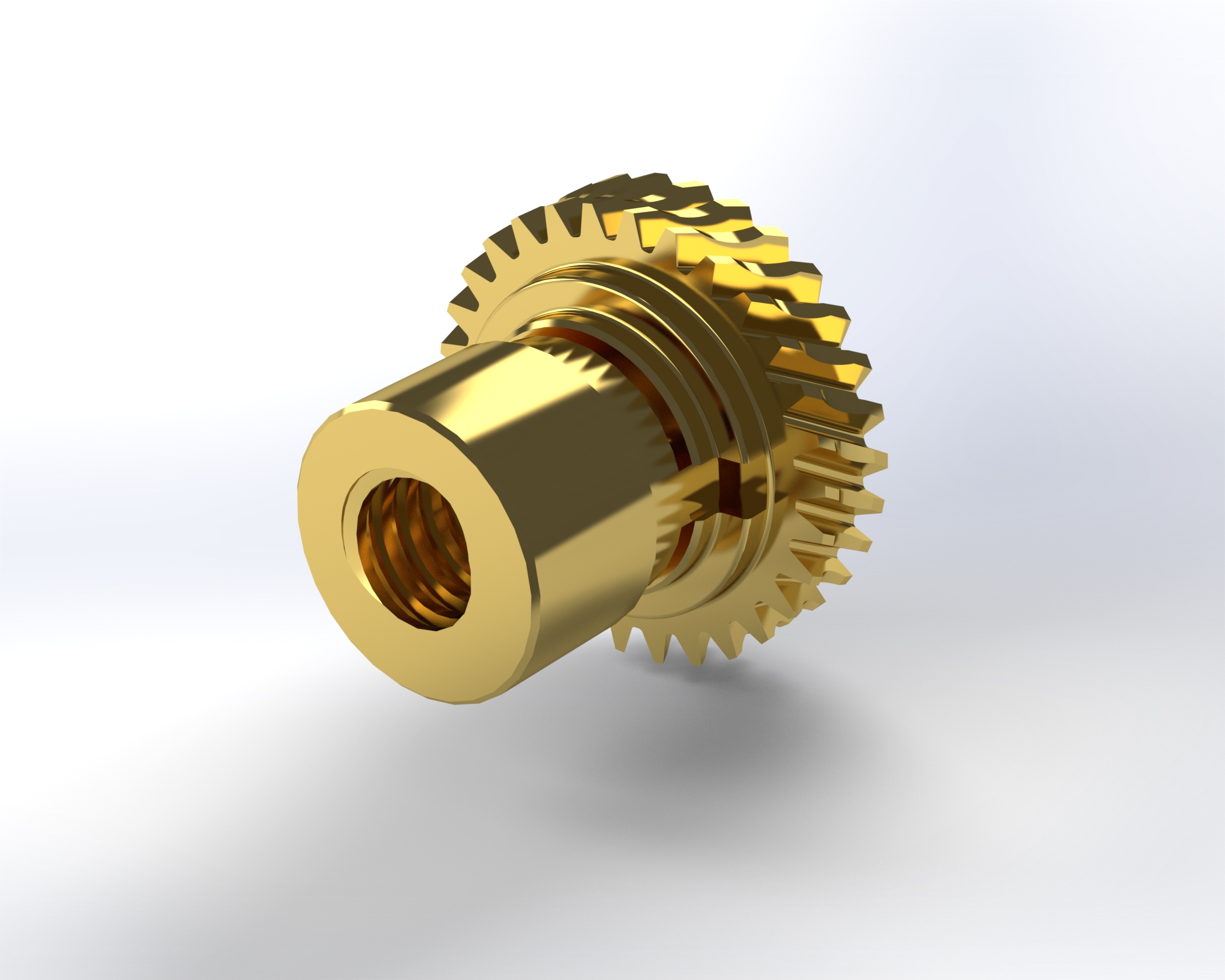

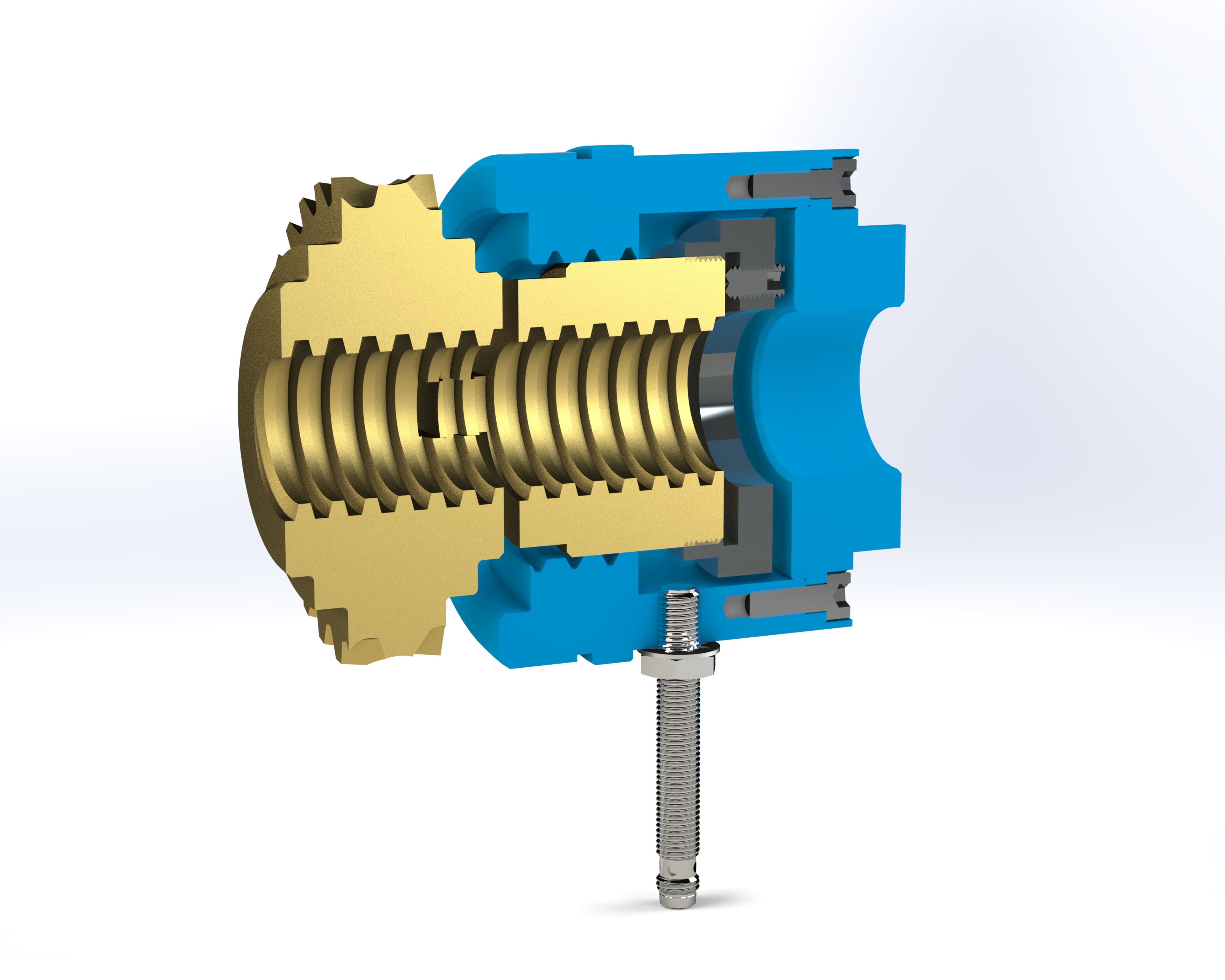

| Worm | 16NiCr4 | EN 10084:2008 | Casehardening alloy steel | Casehardened and ground on teeth and holds |

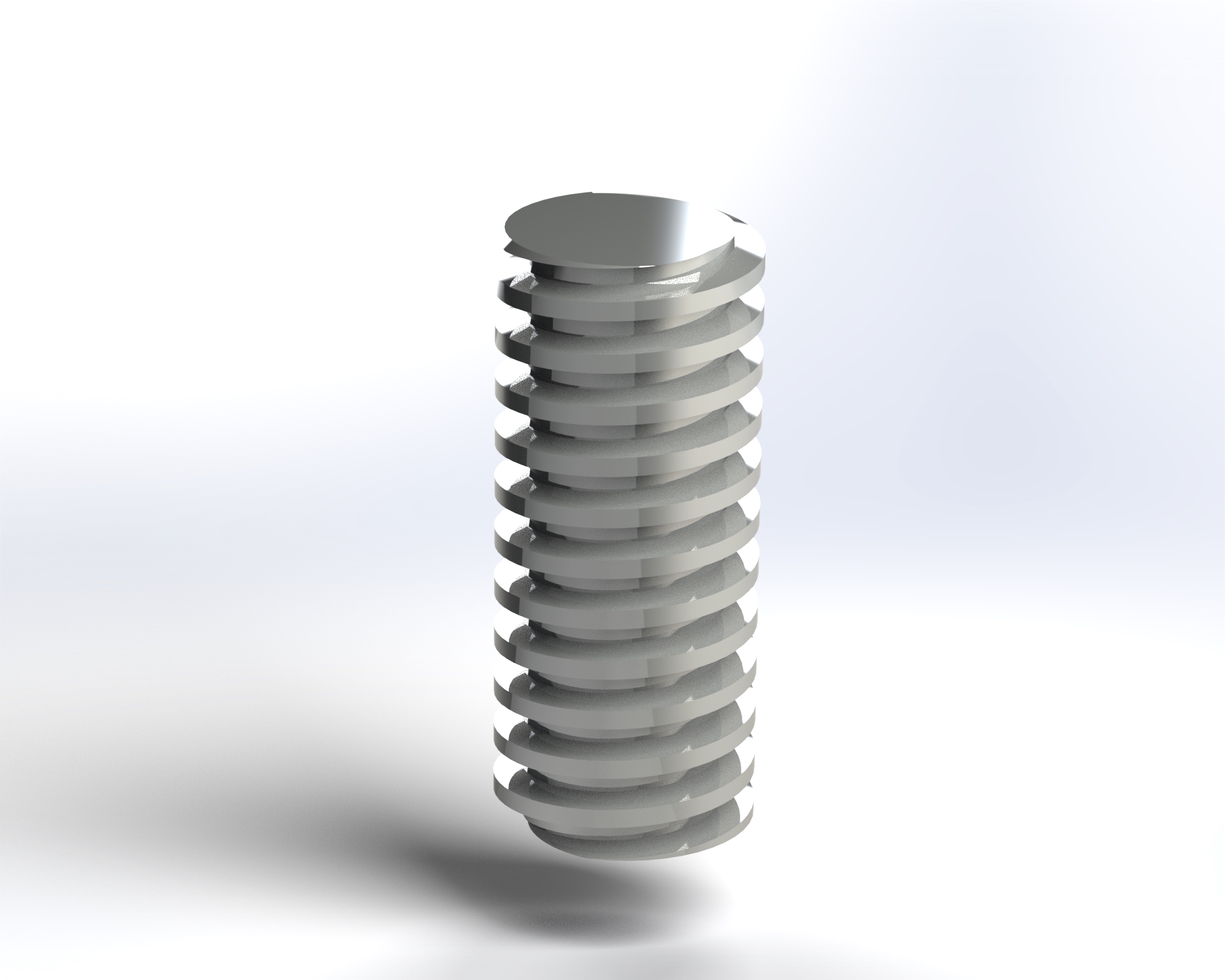

| Worn wheel | CuAl10Fe2-GZ | EN 1982:2008 | Alluminium bronze | Centrifuged |

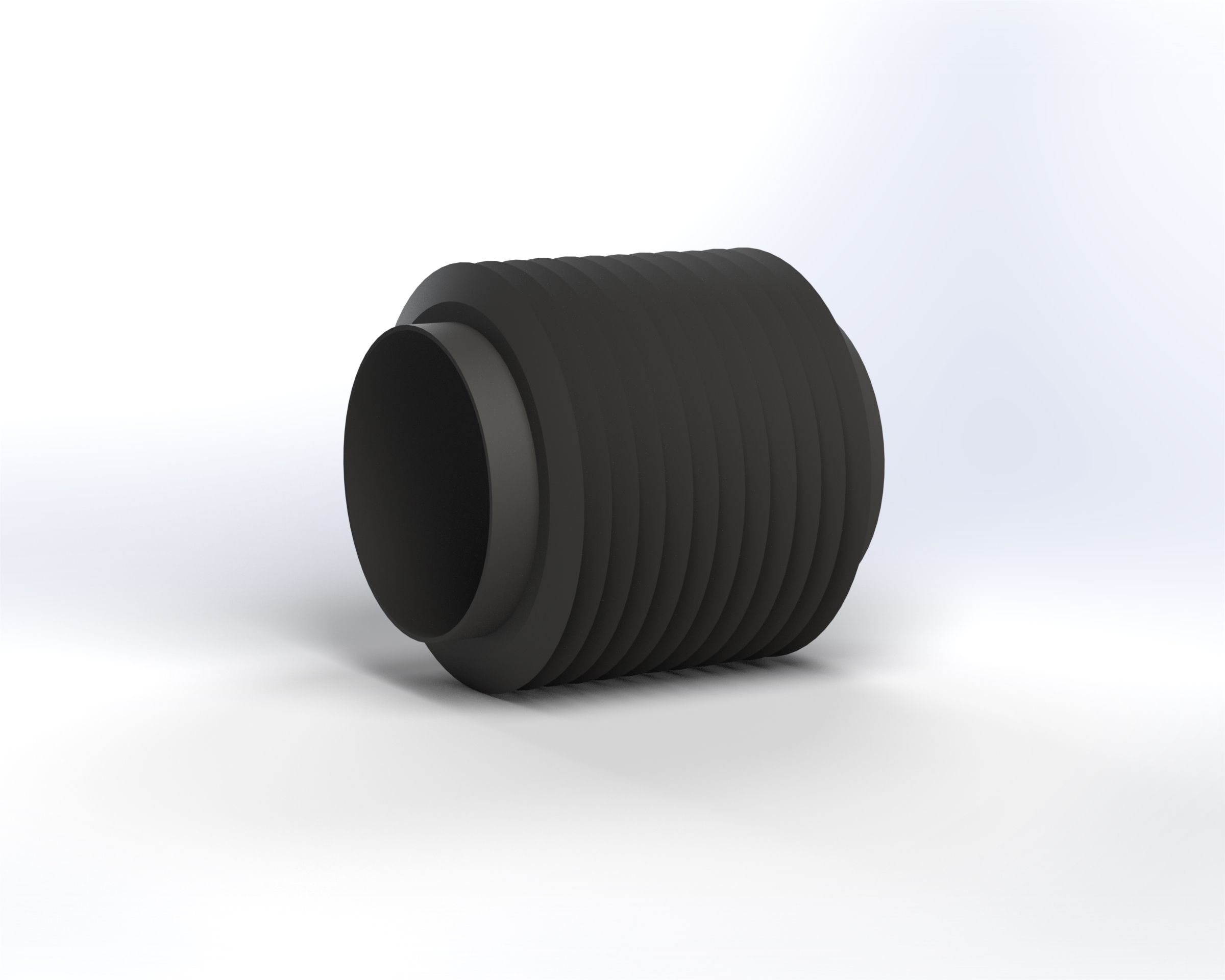

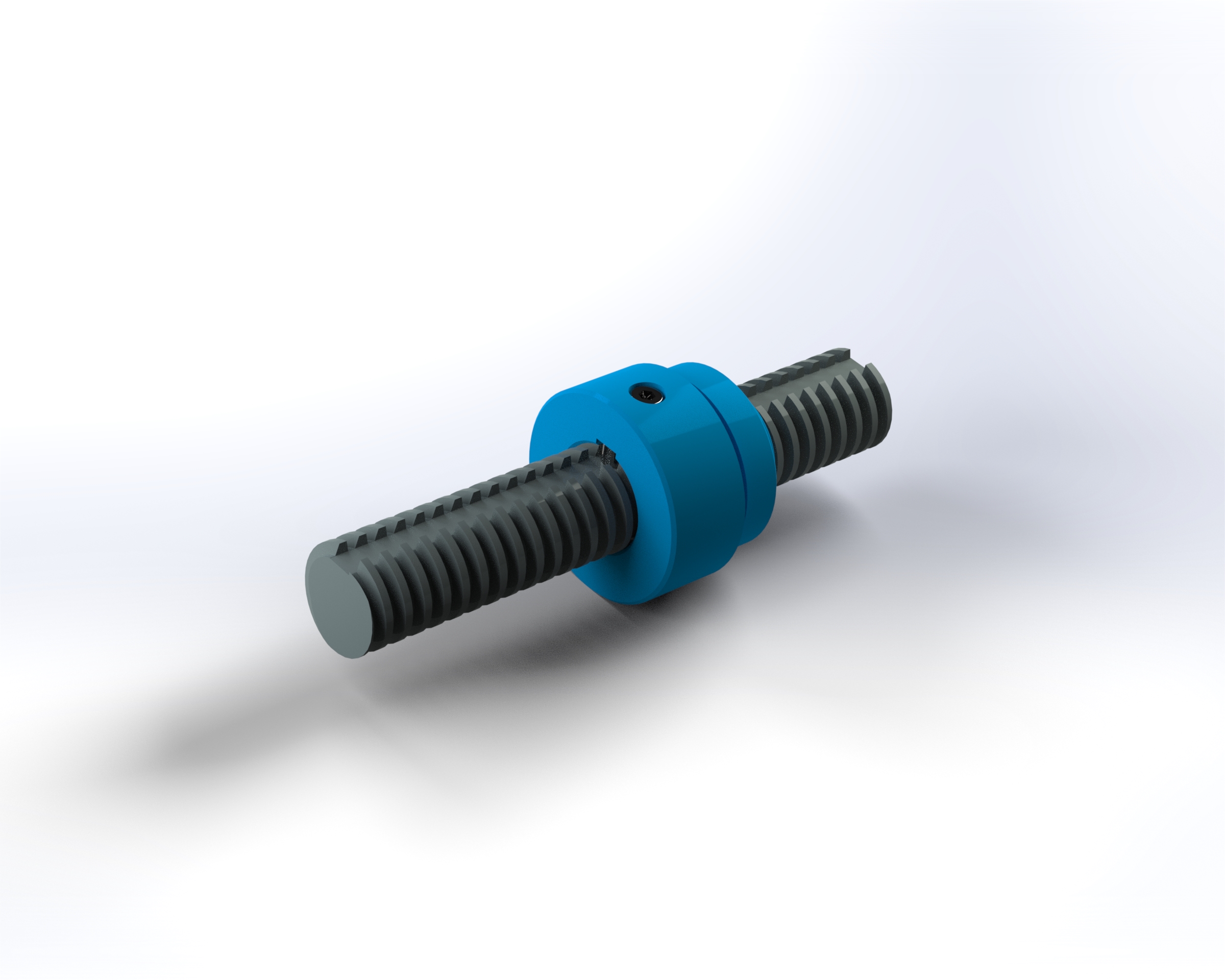

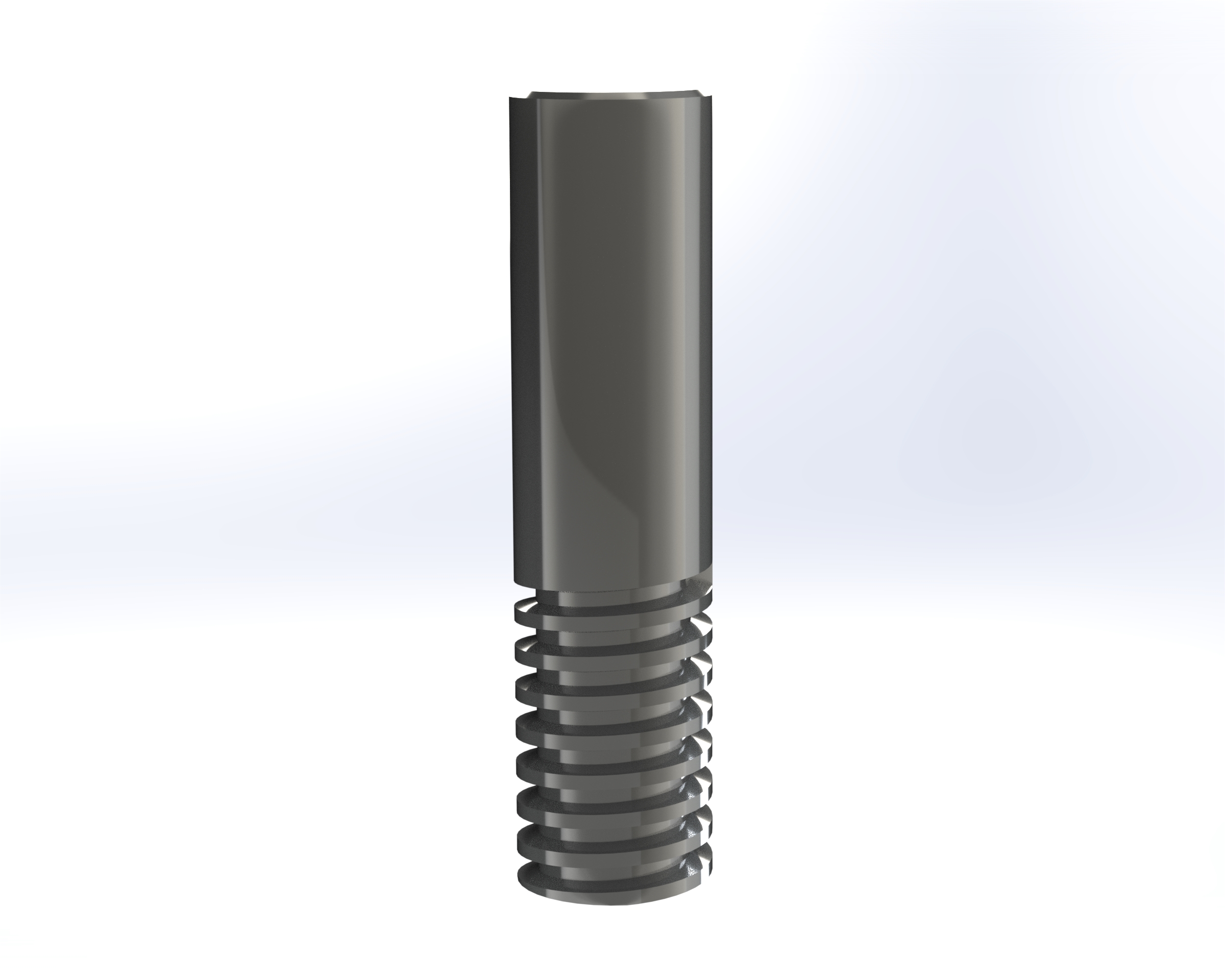

| Threaded spindle | C45 | EN 10083-2:2006 | Carbon steel | Tr 120x14 (ISO 2901:2016) - Rolled or machined |

| Carter | S235 J0 | EN 10025-2:2005 | Welded carbon steel | Completely machined on 6 faces |

| Lubricant | Unimec Mark CA | Calcium based grease | 3,7 kg |

General features

| Operating temperature [°C] | -10 °C / 80 °C |

|---|---|

| Static load (traction or compression) | 850 kN |

| Dynamic load (traction or compression) | 600 kN |

| Maximum input speed | 1800 rpm |

| Main gearbox weight | 180 kg |

| Trapezoidal screw weight | 81 kg/m |

| Anti-rotation torque at maximum load | 5430 Nm |

| Maximum admissible static lateral loads | 10 kN |

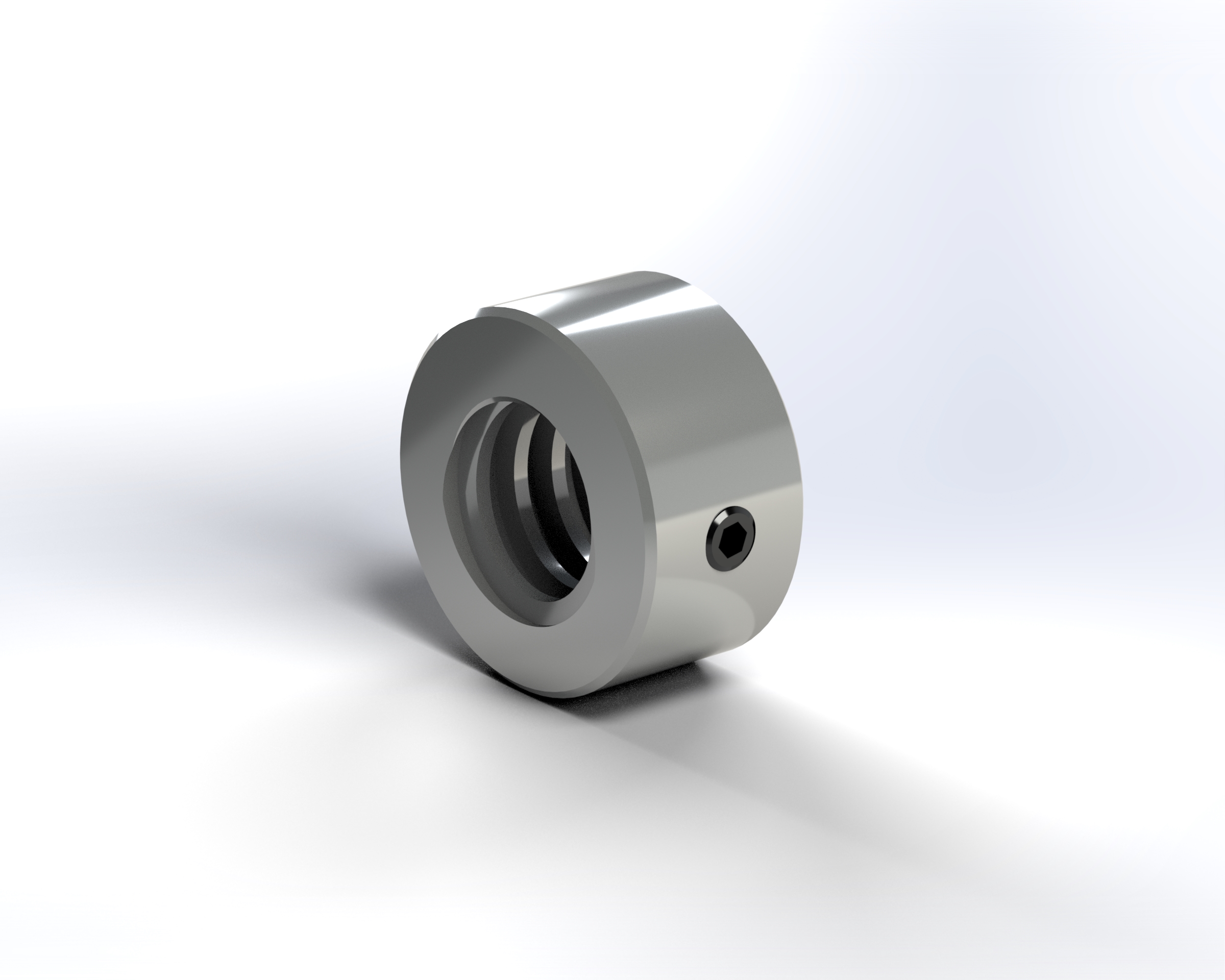

| Center-to-center diameter | 140 mm |

| Maximum radial load on worm | 2,5 kN |

| Standard working conditions | 25 °C - servizio 10% |

Specific features

| Nominal ratios | ||

|---|---|---|

| 1/10 | 1/30 | |

| Real ratio | 1/10,33 | 1/30 |

| Translation per worm revolution | 1,355 mm | 0,47 mm |

| Efficiency | 17 % | 11 % |

| Start-up efficiency | 11 % | 7 % |

| Maximum linear speed | 1050 | 700 |

| Torque at maximum load | 800 Nm | 400 Nm |

| Worm screw maximum torque | 5200 Nm | 4400 Nm |

| Idle torque | 3,95 Nm | 3 Nm |

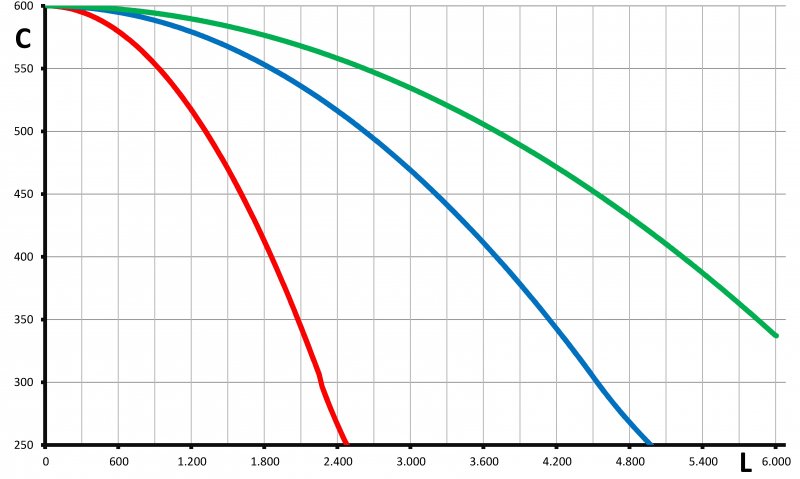

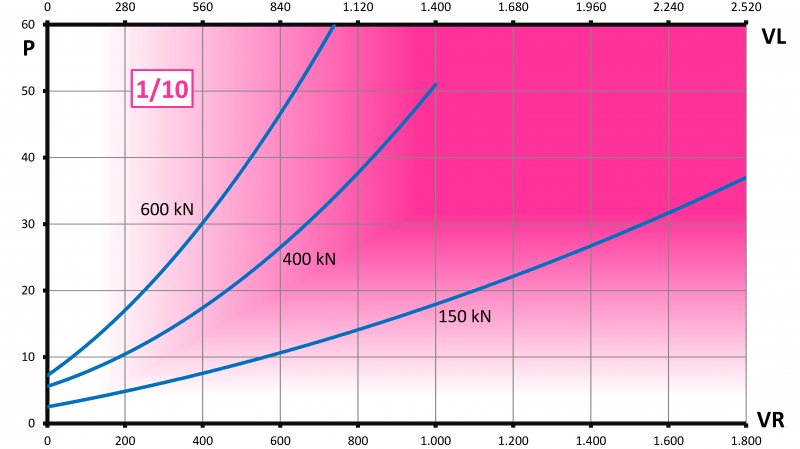

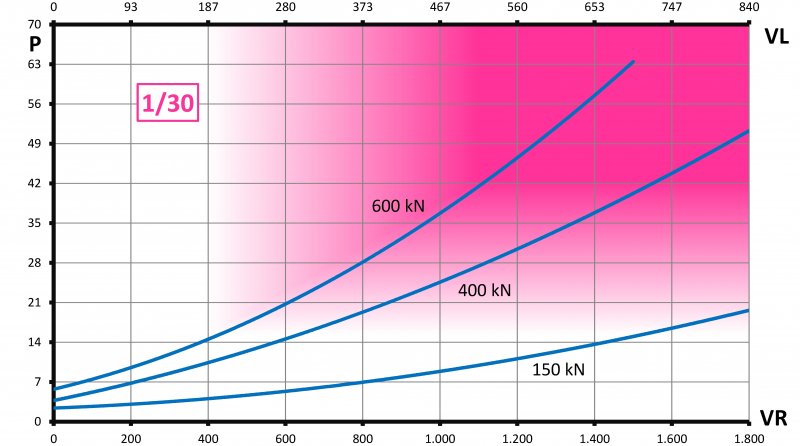

Euler's law (safety factor =2; dynamic compression load)

Limit Load 1 (red) - 2 (blue) - 3 (green)

C = Load [kN]

L = Overall trapezoidal screw length [mm]

Power curves

The magenta zone indicates a potential heating risk. Working cycles must be carefully analized.

VR = Worm rotational speed [rpm]

VL = Spindle translation speed [mm/min]

P = Requested input power [kW]

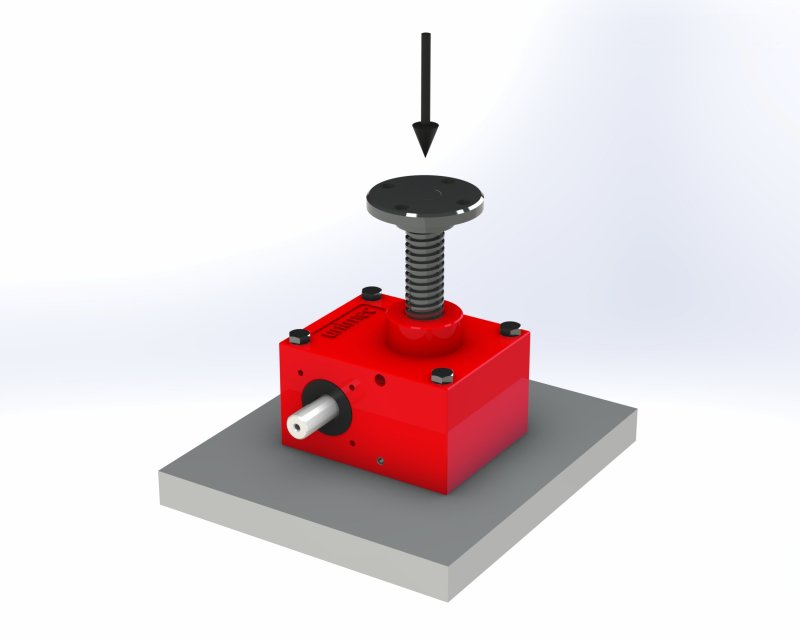

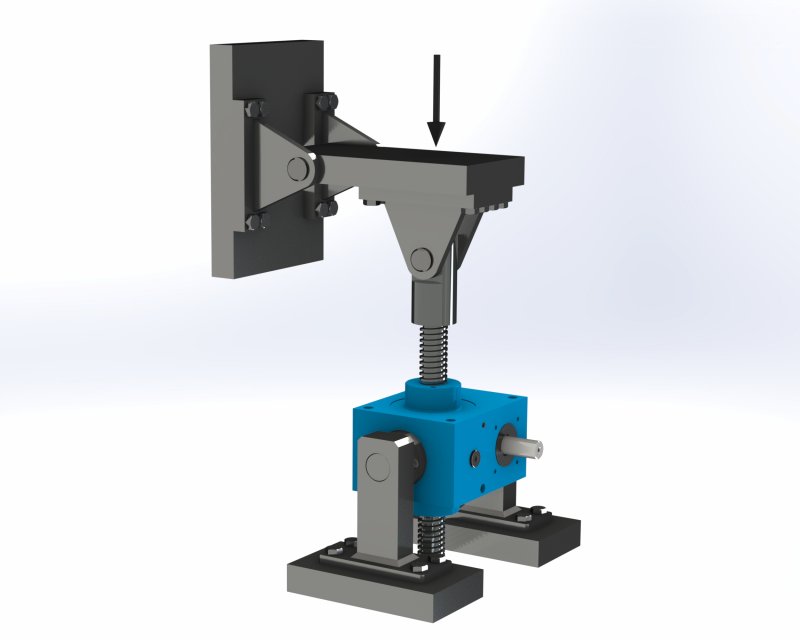

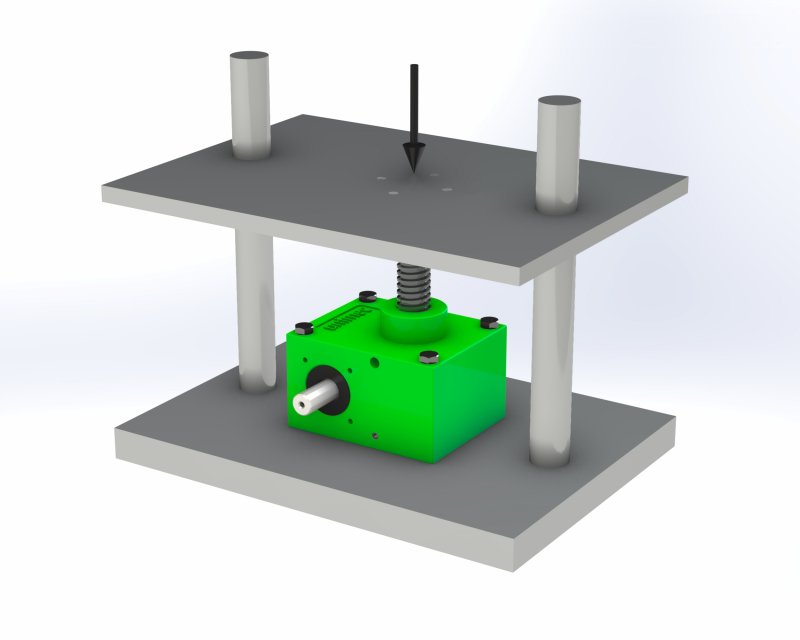

Construction forms

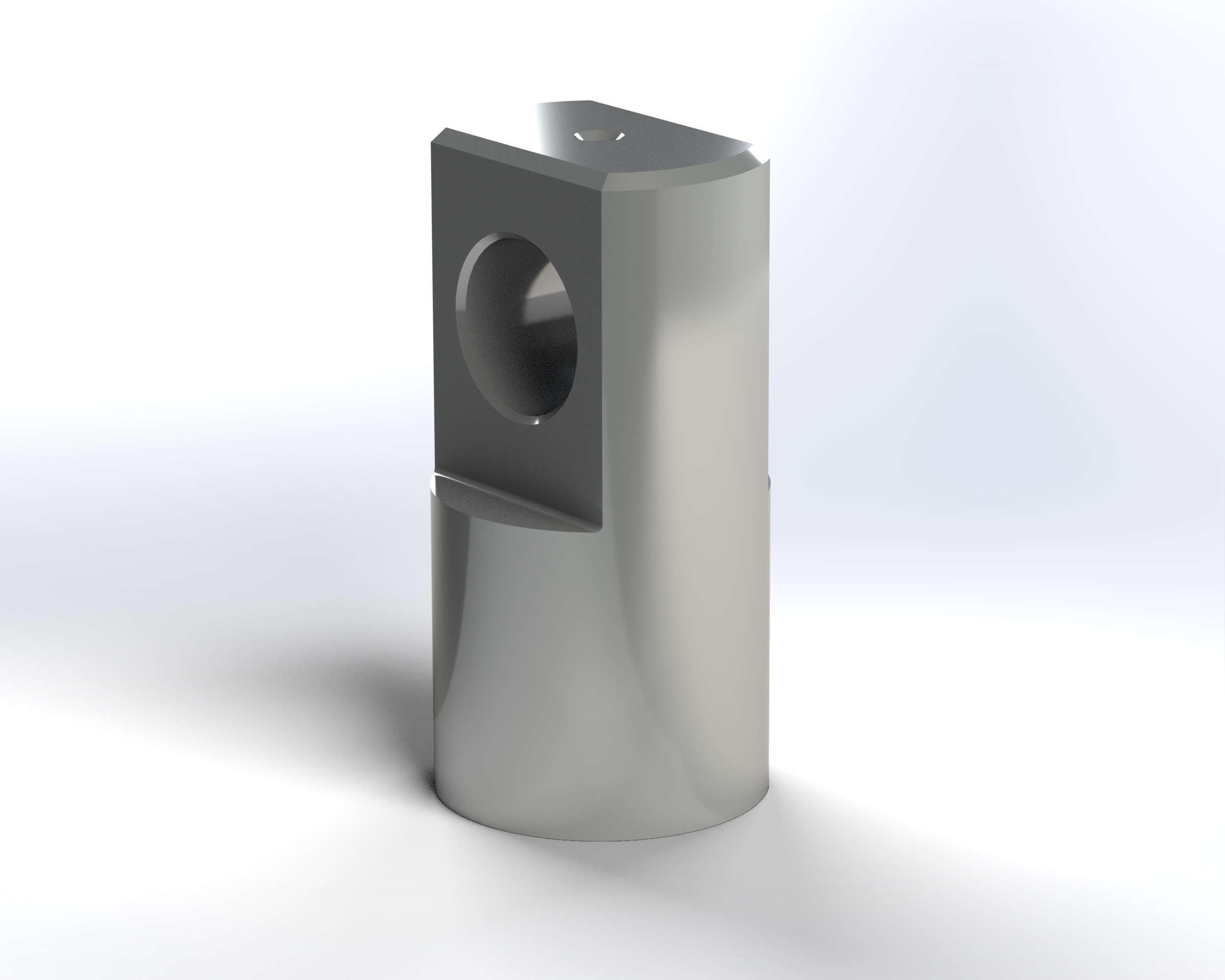

Specific accessories

The accessories avaiable for this product are reported below

Italiano

Italiano

English

English  Español

Español  Deutsch

Deutsch  Русский (Россия)

Русский (Россия)  Français

Français